Listen here on Spotify | Listen here on Apple Podcast

Episode released on October 17, 2024

Episode recorded on July 3, 2024

Doug Owen is a Senior Principal at Stantec and consults with utilities on water treatment and with US EPA and American Water Works Association on policies related to water treatment.

Doug Owen is a Senior Principal at Stantec and consults with utilities on water treatment and with US EPA and American Water Works Association on policies related to water treatment.

Highlights | Transcript

- Globally ~ 360 km3 (444 million acre feet, maf) of wastewater (WW) is produced annually, ~63% is collected, ~50% is treated, and ~11% is reused (Jones et al., 2022; Scanlon et al., 2023).

- US population is only 4% of global population but accounts for ~ 13% of global WW production (~34 billion gallons/day; 38 maf/yr, 47 km3/yr). ~ 100% of WW is treated with the exception of septic tank systems. WW reuse is ~ 11% of total production with projection to ~20% by 2027. (US EPA link)

- No new water on the planet, so we reuse water continually through natural processes or using technology.

- Dual benefits of reusing WW:

- Producing safe, reliable, cost competitive water supply

- Reducing discharges of WW and nutrients to rivers and the ocean.

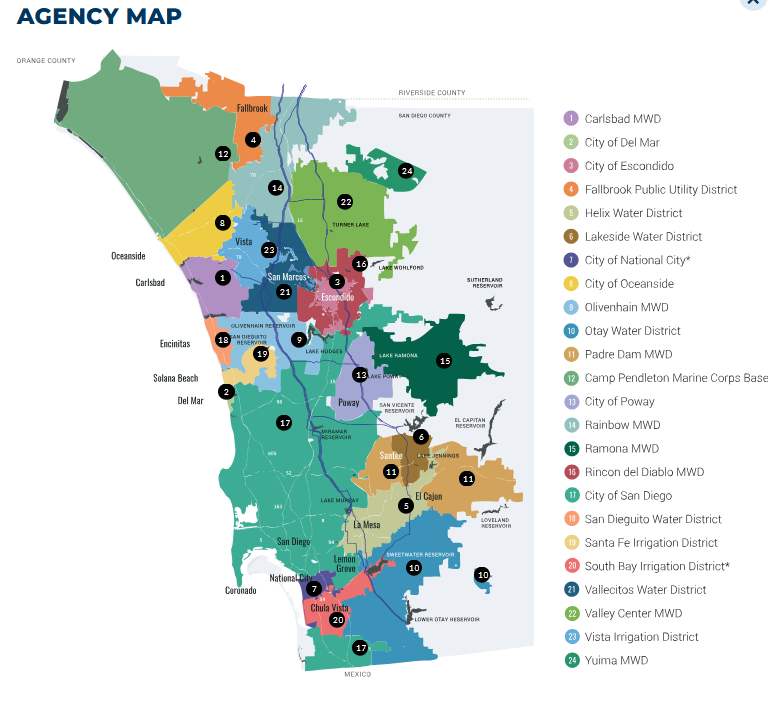

- San Diego, California: imports 85% of water from Colorado River aqueduct or from the State Water Project in the North. Colorado water supply is decreasing because of decadal droughts.

- Goal of developing more local, sustainable, reliable water supply for the city of San Diego (population 1.38 M, 2022)

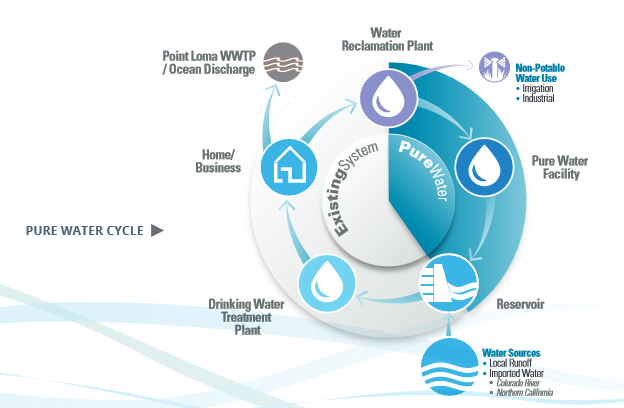

- The San Diego Pure Water Project is designed to treat and reuse WW for the city of San Diego.

- US EPA Clean Water Act (1972) requires that all waters are fishable, swimmable, requiring WW treatment

- San Diego, late 1990s, built 2 WW treatment plants (North City and South Bay), that could produce up to 45 Mgal/d of treated water to use for irrigation and commercial/industrial purposes.

- National Academies reports titledPotential for Expanding the Nation's Water Supply Through Reuse of Municipal Wastewater (2012a) greatly advanced the drive to reuse WW in the U.S.

- Pure Water San Diego is designed to use treated WW to produce high quality drinking water that will be released to a surface water reservoir. There are two phases to the project and it is designed to provide the City of San Diego with up to half of its water supply when completed.

- Over a century ago, WW was discharged in streets and to rivers in urban areas (London, Paris etc), relying on dilution to manage contaminants.

- Increasing population densities in urban areas overwhelmed the assimilative capacity of rivers and required treatment.

- WW treatment:

- Primary treatment: settling basins, removes ≤60% of suspended solids. (residual has high oxygen demand, causes eutrophication)

- Secondary treatment: Basins, injected oxygen, grow microorganisms (activated sludge), organisms eat soluble material, transferred to settling tank. Treated WW has much lower O2 demand. Digest the organisms (digesters, no O2) and end up with methane gas. Sludge could be used for landfill cover or soil amendments.

- Tertiary Treatment: Filter WW, disinfect it, then it can used for irrigation or industrial purposes.

- Additional work, activated sludge, specialized microorganisms to remove nutrients (N and P), N à N2 gas, P into sludge.

- San Diego receives a waiver and can discharge WW that receives only enhanced primary treatment (>80% solids removal) because of the large assimilative capacity of the Pacific Ocean.

- Advanced treatments: Ozone/biological activated carbon, membrane filtration, Reverse osmosis (removes all but small ions), UV Advanced Oxidation Process. Resultant WW is demineralized, needs additives to provide buffering capacity and bring pH back up.

- Comparing different water options for San Diego:

- Potable WW reuse: Salinity of WW, ~ 1,000 – 1,500 mg/L Total Dissolved Solids (TDS).

Energy required to treat WW (reverse osmosis) varies with the salinity of the water.

Seawater, 32,000 – 36,000 mg/L TDS, ~33% to 50% more energy required for RO than WW treatment for potable reuse.. - Carlsbad Desal facility: produces ~ 50 Mgal/d for San Diego County, the largest seawater desalination facility in the US. The county has a take or pay contract for 30 years with Carlsbad Desal facility. Freshwater recovery from the desal plant is ~50%, resulting in brine ~ 2× the salinity of seawater. This brine is mixed with recirculated water from the Pacific Ocean before discharging to the Pacific Ocean.

- Potable WW reuse: Salinity of WW, ~ 1,000 – 1,500 mg/L Total Dissolved Solids (TDS).

- San Diego Pure Water is an indirect potable water reuse program discharging purified water from WW to surface reservoirs (Surface Water Augmentation; Miramar Reservoir) because there are no suitable aquifers to recharge.

- Surface water augmentation is more expensive than aquifer recharge because of water transfers from low points to higher level elevations where reservoirs are located.

- Orange County Water District, where Disneyland is located, generates 135 Mgal/d of treated WW and recharges aquifer through direct injection and spreading basins.

- California receives 4.4 maf (5.4 km3) of water per year from the Colorado River. The city of San Diego receives Colorado River water through the County Water Authority and a long-term contract with Imperial Irrigation District.

- Movement for water utilities to becoming watershed centric, One Water concept.

- Centralized WW treatment benefits from economies of scale but may incur larger distribution costs than decentralized systems. Need to assess tradeoffs between treatment and distribution costs.

- If making agreement between WW treatment and industry, need long-term reliable customer, such as Palo Verde Nuclear Plant in Phoenix who buys 91st Ave. WW Treatment Plant discharge.

- Relative costs of different types of water:

- San Diego County Water Authority: treated imported water, $1,930/af (2023)

- Carlsbad Desal: $2,500 - $2,800/af (2020) to $3,400 in 2024, includes conveyance costs

- San Diego Pure Water: $1,700 - $1,900/af

- San Diego buys water from Imperial Irrigation District (Colorado River Water) for $710/af. Irrigators pay ~ $20/af in IID. link

Units: 1 m3 = 264 gal; 1 af = 325,851 gals; 1 maf = 1.233 km3